Thanks to the economic upswing, suppliers of packaging and labelling machines for the Dutch food processing industry have the wind at their back. However, that doesn’t mean that customers are so eager to spend money that they lose sight of the goal of their investment: efficiency. What it does mean is a greater focus on quality and sustainability; the food industry is once again taking a long-term view.

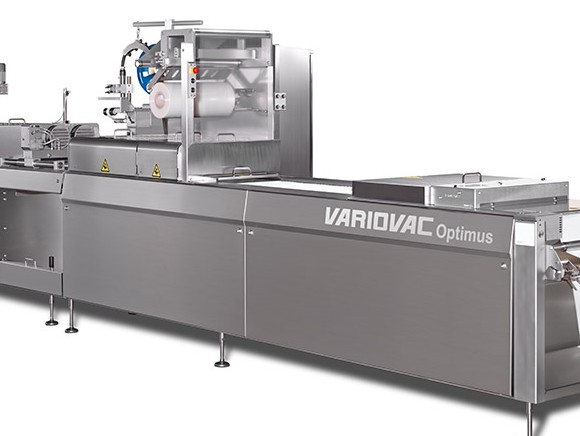

One person who is feeling the effects of this is Stephen van Uhm, who has been at the helm of the Borne-based family-owned company Van Uhm BV for the past four years. The German machine builder Variovac’s thermoformers were added to Van Uhm BV’s product range in 2015 and he is noticing a growing market interest in Variovac’s solutions. “That’s due to the robustness of the machines – they are typical examples of ‘Made in Germany’ – and their high output.” According to Van Uhm, the rise in demand for the vacuum packaging lines of another German machine brand – Boss Vakuum – also illustrates that more and more companies in the food industry are now choosing to invest in durable quality again.

Another benefit for manufacturers is that the cleverly designed Rapid Air technique enables them to use a smaller vacuum pump to achieve the same results, requiring less maintenance and less space. The Variovac brand was not particularly well known in the Netherlands before Van Uhm started representing it. “But we’ve already installed more than ten machines. We pay a lot of attention to the brand and to providing good service, and that definitely contributes to our success,” comments Van Uhm. The majority of the Van Uhm mechanics have also been specially trained in the technology of the Variovac machines.

Furthermore, Stephen van Uhm is seeing a growing need for machine flexibility in the industry. “There is a high demand for machines that can work with various types of films, including films for skin packaging which continues to gain in popularity. The Variovac brand offers solutions for that too.” This need for flexibility is producing innovation and advancement, such as a recently launched new edition of the Variovac Optimus which provides more possibilities to connect auxiliary equipment.

At De Koningh Coding & Labeling, they have identified a different topic as the key trend. The Duiven-based company, which is the biggest independent supplier in its market, is receiving more and more requests for total solutions, according to Marketing Manager Steven Aldershoff. “Customers want to source machines, supplies, software and service from a single supplier, and they are increasingly focusing on things like how the software can be integrated with their ERP system, for example. In the world of product and packaging identification, everything revolves around having the right information in the right place.” For Aldershoff, it is only logical that a growing number of companies nowadays prefer to work with a single supplier for all their coding and labelling activities. “A total solution results in better quality. All the elements are aligned with one another and there’s no discussion about whose responsibility it is if anything should go wrong. You want to avoid production downtime or recalls due to incorrect product information. They cost a lot of money after all, plus a recall damages the trust that you’ve built up through a commitment to quality. Retailers as well as consumers place high demands on safety and reliability, and you don’t want to take any risks with those aspects. Moreover, a good product identification system improves the durable quality of the process. Errors lead to downtime, repacking of products and waste. Needles to say, eliminating errors considerably reduces waste, and that’s what we do.”

Greater demands are also being placed on the amount of information manufacturers must provide, both in response to consumer expectations and due to legislative requirements. “There are limits to how much you can include on a label, but we offer relevant solutions such as using a QR code to link to more information. Today’s consumers want to know more about the origin of the food and drink they buy, and the industry considers it important to be transparent.” With their preferences for appealing packaging, consumers are also driving another new trend that Aldershoff mentions: “More and more customers are utilising our colour printers. This is an emerging technology which requires knowledge of printing technology, inks and substrates. The pace of production is high and the drying times are short. It’s a challenge that we enjoy tackling.”

Supplier Espera is focused on machines and solutions for weighing and labelling pre-packed consumer products, primarily fresh foods. Around 90 percent of its business comes from the fresh segment, explains Jan Zwaan who heads up the German company’s Dutch activities: “Our customers have to comply with labelling legislation, plus consumers want to be provided with certain information.” Zwaan too has noticed that the amount of information that must be listed on the label has grown considerably in recent years and he mentions the dynamic QR code as one of the solutions that enables manufacturers to tell the whole story about a product. “The industry is making a virtue of necessity. In the wake of the recent food scandals, the food industry is now showing people that it has nothing to hide and that the entire process is transparent.”

Zwaan sees the industry changing in other ways too: “Lead times are getting shorter, the production activities are switched more often which means more changeovers. Our labelling machines are designed with that in mind. Besides that, it’s getting harder to predict exactly how manufacturing will evolve over time. What demands will the market place on production, packaging and labelling in the future? Just look at how the number of labels on a product has changed. Added to that, manufacturers’ supply contracts with customers – such as retailers – are becoming shorter all the time. You can be replaced by a competitor for whatever reason, resulting in you having to scale down your production. Things like these all require greater manufacturing flexibility. Espera was founded 92 years ago and we first started developing modular systems in the 1970s. These are aligned with the conditions in today’s food processing industry. A manufacturer can choose to purchase one module now and hold back on the purchase of their next module until their situation is clearer.”

Zwaan still sees plenty of opportunities for companies to further eliminate the chance of errors, such as by automating processes. “You want to exclude the chance of something going wrong because an operator has a momentary lapse of concentration. One good solution in this case is our vision system. It has been specially developed to check labels, plus it allows you to register how a pack has been placed in a box.”

Sustainability, packaging advancements, dependability and service are the most important topics for customers of Multivac, a German family-owned manufacturer of packaging machines, according to Mart de Koning, Marketing Manager for the Netherlands. “Sustainability includes things like switching from pneumatic-based processes to servo motor drivers, which are more efficient. In terms of packaging advancements, skin packaging is at the forefront. Initially it was only used for high-value products such as steak, but nowadays it’s not unusual to see hamburgers being sold in skin packs too. Skin packaging enables products to be displayed differently – more appealingly – in stores, such as vertically.” Service and dependability go hand in hand, continues De Koning. “We’re also taking care of the maintenance for a growing number of customers.” Multivac guarantees higher output and better cost control to everyone who combines a machine with a service agreement. There is a growing preference among customers for outsourcing maintenance: “The order input is increasing.”

The suppliers are all in agreement that there is one pitfall that their customers – food processing companies – must avoid, namely a short-term perspective. They emphasise the importance of good and timely advice, and of a clear view of the total cost of ownership. In other words: don’t just focus on the purchase price of a reliable machine. In these times of economic growth, it seems that more and more entrepreneurs are starting to heed that advice again.

Source: © De Koningh Coding & Labeling, Multivac, Espera en van Uhm