MULTIVAC was once mainly a supplier of thermoformers and vacuum chamber machines. Those times are long gone. We do much more now. Do you want an entirely new packaging line? We take care of the project from the very beginning all the way to taking the line into production.

It starts with determining the type, the size and the shape of the packaging. We organise test productions of all types of packaging in our application centre. This way, as a customer, you get to see and feel a true-to-life version of the design. If adjustments are necessary, this is not a problem at all. We simultaneously look at how we can implement the line. We offer a very wide range of packaging solutions with extensive options in terms of the application, capacity, budget, and length of the packaging line.

As in the past, we still have fairly simple machines for vacuum packaging products. However, these days, the market requires broader solutions: machines that are multi-purpose, can process both hard and flexible films, and/or can produce both skin and MAP packaging. We offer all of these as standard options.

The demand for total solutions is growing. Customers want more than just a packaging machine; they also want to have all peripherals implemented. We meet that demand, for instance, with options for automatically filling through a sauce pump, a multi-head weigher or a robot. We also offer various solutions for printing films or adding labelling to the packaging. Fully automatic and fully integrated in the machine.

There are standard and custom solutions for transporting the packaged products. Think of the well-known in-liner, or - as we are seeing more and more often - a robot solution that offers more flexibility.

Perhaps you want to add a checkweigher, with a metal detector or an X-ray to detect contaminations in the packaging? You can! We also have a variety of solutions for sticking labels onto packaging: ‘simply’ on the top or bottom, but there are also options for complex label positions such as a C, D or L label.

The packaged products are placed in boxes or crates at the end of the line. You can do this manually, but we can also fully automate this step for you by means of a robot solution.

The packaging line has been placed and everything is working. But our job does not end there. Do you want to train your operators? Our specialists can give them complete training, both on site and in the MULTIVAC factory in Germany; whichever you prefer.

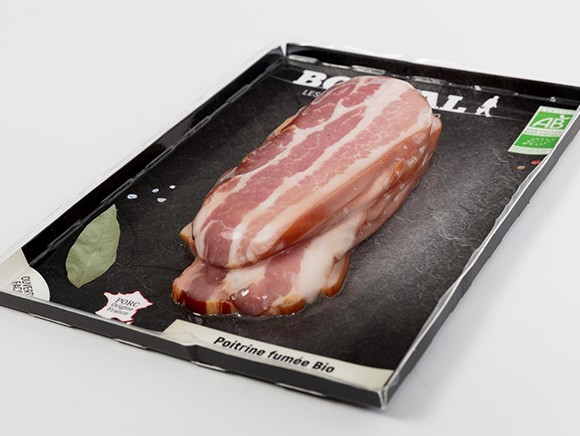

Sustainability is a high priority all over the world. When it comes to packaging food, this mainly comes into play in the choice of packaging material and avoiding food waste. The Trayseal technology by MULTIVAC gives fresh food products a longer shelf life. Very suitable for fresh fish and meat products, dairy products, ready-to-eat meals and processed vegetable and fruit products. In part due to the great variety of trays (dishes and bowls) with different shapes, sizes and materials. Of course also with renewable, recyclable and/or compostable plastic and cardboard. The trays can be sealed with many types of cover films.

The automatic Traysealers from MULTIVAC are very suitable for packaging relatively large production quantities, such as for the production of MAP, EMAP and vacuum skin packaging. We can equip the machines with things like automatic tray denesters, filling systems, label applicators, robots and various transport systems. Quickly and easily switching to a different tray size on the same machine is no longer a problem. In addition, it is not necessary to organise filling the trays on the machine. This can also occur prior to the sealing process.

Of course, it is also possible to package relatively small and medium-sized production quantities of food products, such as with the MULTIVAC semi-automatic Traysealers. The compact size and mobility of the semi-automatic machine series makes it very flexible in use.

Source: © Multivac