Compared to other sectors, the food sector still has a relatively low robot density. But the sector is catching up. Big data technologies such as data analysis, data mining, and artificial intelligence are turning the agrifood chain - from ground to mouth - fundamentally on its head.

The future for robot producers is promising. Last year, the sales of robots increased with 30 per cent and the annual sales volume of industrial robots increased with no less than 114 per cent over the past 5 years (2013-2017). The figures were announced in October by the International Federation of Robotics (IFR). The organisation speaks of 'a successful development of the global robotics market'. According to the IFR, industrial robots have become a crucial part of the progress in the manufacturing industry. And they evolve continuously thanks to a multitude of innovative technologies such as vision technology, artificial intelligence, and simplified operating systems. We can see robots doing work for us in all kinds of sectors, at home and in the workplace, in shops, hospitals, stables, and factories. And thus increasingly often in the agrifood sector as well.

This was also picked up by ABN AMRO in their report 'Robotisation in the Food sector', which was published in October. According to the bank, the rapid advance of robots in the food sector is mainly caused by the emergence of big data and artificial intelligence. But even though the technology is ready, the deployment of robots in the food sector still remains tricky. "A robot acts best in a controlled environment. But fresh products, such as peppers or tomatoes, vary in size, shape, and weight. This means that the processing lines must be flexible. And this is exactly the main challenge for robots", says Nadia Menkveld, Sector Economist Food and Agriculture of ABN AMRO. "With the rapid developments in the areas of AI, big data, and mechanics, this situation is now changing. All signs indicate that the food industry is ready to embrace robotisation." But this is not entirely realistic. At least, not according to Schouw Informatisering.

Are food processing companies ready for the future? That was the key question in the 'Trend Report IT Food Forecast' (also published in October). This independent study was conducted by RVS agency and commissioned by Schouw Informatisering. The answer is clear: 'No, they are not'. The researchers do notice a growing need for more efficiency in the food industry as well as the opportunity for rapid innovation. However, in order to do this, further insight is required, as well as a grip on the chain and on internal processes. And that is a bottleneck. 'Breaking through existing structures and accompanying investments are hindering rapid changes', the report says. 'Many organisations are simply facing the digital limitations of their platforms and ICT architecture.'

Most companies manage to collect the data that will give them the required insight. But being able to rely on reliable management reports is a major challenge; not when it concerns the quality of these reports, but mainly with respect to the way they were compiled. 'An outdated work method results in a loss of efficiency and increases the margin of error. There is still a good amount of data that remains untapped', is the conclusion of the report. 'The increasing importance of traceability, sustainability, and food safety, combined with the necessity of innovations which have an increasingly shorter time-to-market, requires modernisation.' According to Schouw Informatisering, the relative low IT investments are the reason why the sector is lagging behind.

Nevertheless, when a company does invest and these structures are, therefore, not outdated, the benefits that robots provide in the production process can be substantial. Companies can use the data they collect to organise their processes even more efficiently, products can be traced faster, and chains are shortened. Robots can also offer an important contribution to the battle against food waste. Nadia Menkveld (ABN AMRO): "Every product has gone through the system. When the quality is not as good as expected, the whole lot can be easily traced and the supplier can be clearly informed."

Robotisation can also be an answer to the shortage on the labour market in the food sector. "Due to the tight labour market, more and more companies find it hard to recruit personnel, which can impede their growth", explains Nadia Menkveld. "Furthermore, the labour conditions in the food sector are not always pleasant. For instance when personnel has to cut vegetables or meat in a cold environment. The further automation of processes using robots will first mean a substantial investment. It also leads to a different type of jobs; work that requires employees to gain new skills."

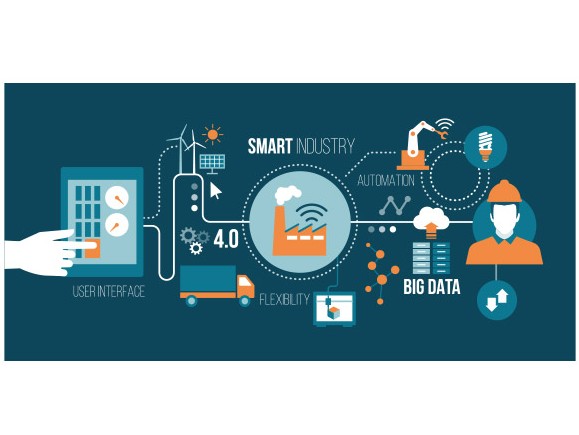

Despite the differences, all three reports agree on one thing: it is expected that the chain integration will increase and there will be a higher level of data exchange; in part to respond to the demands of transparency and traceability, and in part to prevent food waste. The direct, online sales to the end consumer will rise further. Additionally, innovative solutions which become available via the Intelligent Cloud and blockchain-technology will gain in importance. Combined with developments such as the IoT (Internet of Things), blockchain, 3D printing, and nanotechnology, this will lead to new business models and opportunities for business owners.

Great, all that data! And it goes without saying that the exchange of data and information is essential. In the meantime, however, hacks both at home and abroad are shutting down entire companies, banks, and institutions, with increasing consequences. In the old days, IT (Information Technology) was a world apart from OT (Operation Technology). Nowadays, these two worlds are getting more and more integrated. This is why Rianne Boek of NEN and Marcel Jutte of Hudson Cybertec are now collaborating within NEN in order to give cyber security a more prominent position in the industry. "Standardisation is an absolute necessity", says Rianne. "But it is quite hard to stay abreast when it comes to its application and how you keep updating it with the rapid changes within the OT and IT, as well as in legislation. Especially when cyber security is not your line of business." For companies and institutions that are struggling with this, there is the Industrial Platform Cyber Security (IPCS). Rianne about the need for this platform: "Our world is more and more reliant on the internet of things (IoT) and, consequently, on the related industrial internet of things (IIoT). Lamps, speakers, temperature sensors, the doorbell, they are all connected to the web, they can be read and/or operated remotely, and they have their own IP address. They exchange data with each other, and with us humans. Everything is measurable and can be independently or collectively operated. It is the future of the industry; that much is certain. But what does this mean for the security? This is also a topic about which the platform exchanges information."

Flexible production against the cost price of mass production: it is crystal clear that robotics play an important role in the realisation of this goal. But other technologies, such as operator support and smart process management are also necessary. These developments bring new challenges: which standards do we need in order to make all these technologies properly collaborate with each other? How can we safely implement robots in the production process? And which international standardisation developments are consistent with this? Many entrepreneurs discover that interfaces between robots are often supplier-specific. This means that not every robot can be connected to every robot arm. That is a problem and everything but flexible. This is why the NEN is of the opinion that standards and guidelines for robot modularity are required. When it comes to safety, there are other challenges as well. For example: how can you deploy robots that collaborate with people, the so-called cobots? Must such work areas be screened off, or are there other methods to use such a robot safely? This requires standards as well. The 'Smart Industry Standardisation' platform has organised a knowledge session which will take place on 13 November (the day this magazine is published). "Within Smart Industry, the standards from ICT and the manufacturing industry will come together to enable a better collaboration. It is extremely important that companies know where they can turn to for Smart Industry standardisation, and that the Netherlands joins the right international initiatives in time", says Rianne Boek.

People are already working on a concrete implementation of standards and guidelines. In October, TNO came with a proposal for essential safety and health requirements in the area of machine safety (see box). This will have to make the Machine guideline future-proof. This guideline mainly focuses on machines that have incorporated machine learning, as machines (it is getting increasingly difficult to distinguish machine from robot) are capable of doing more and more. TNO conducted a desk study and interviewed experts in the field of robotics and machine learning. The results of this study can be found in the report 'Essential V&G requirements for industrial machines with incorporated machine learning'.

The links to the reports mentioned in this article can be found on www.vakbladvoedingsindustrie.nl.

Some proposals for essential requirements from TNO are:

Machines with machine learning technology must be capable of:

-adequate and fitting reactions to man, indicate which actions the machine is going to undertake, and based on which information.

These machines should not be able to make decisions or considerations:

-in relation to damages to man and environment which lead to actions by the machine outside their defined task and clearance.

Actions by these machines must be traced beforehand and afterwards based on:

-transparency in the applied data sets, test environments, and assessment frameworks, or on testing criteria for decisions and algorithms.

The decision-making process of a machine with machine learning must be logged and stored.

Source: © Willyam Bradberry/Shutterstock.com, © Elenabsl/Shutterstock.com. © Vectorfusionart/Shutterstock.com